Share

Author

George Anderson

Share

First published Jan 6, 2021. Updated Aug 28, 2023.

In the post-COVID economy, manufacturers are striving for efficiency. That’s especially true when it comes to order entry methods. Many manufacturers still depend on phone, fax, and email to take orders from customers. COVID has turned these models on their heads, forcing manufacturers to transform their customer experience.

How can you start reducing your cost of order entry? Let’s unpack the low-hanging fruit.

1. Replace phone/fax/email orders with self-service

How do your channel partners place orders today? What options do they have if they don’t want to use EDI or can’t afford it?

In this situation, most manufacturers rely on phone, fax, or email ordering. The process often includes several steps of manual, back-and-forth communication. To initiate the order process, your channel partners call, email, or fax customer service or sales to ask about pricing and availability. They may take that information back to an approver (if applicable), then call again to place the order.

NEW Report:

Optimizing OTC Processes for Manufacturers

Every manufacturer needs to become more efficient. Here’s the ultimate guide to optimizing your OTC cycle. Read now.

This process isn’t scalable. Your cost-to-serve scales up alongside order volume, which reduces efficiency in your OTC cycle.

A self-service ordering portal can eliminate the cost of giving the customer personalized data from SAP—but the portal must include real-time SAP integration. That’s the only way to eliminate a high-cost middle layer standing between the order origination point and the ERP.

Here’s what that looks like:

We’ve got four processes here for order entry, and they’re arranged from least efficient to most efficient.

- Phone/fax/email ordering (least efficient). Customers must use a legacy communication technology to speak to a CSR (customer service rep), who must re-key the order into the ERP.

- Web portal without ERP integration. Customers can place orders online, but CSRs must re-key those online orders into the ERP (and call customers back to rectify any order errors, disallowed SKUs, wrong quantities/prices, etc.).

- Web portal with batch synchronization to ERP. Customers can place orders online, but the ERP integration isn’t real-time. This means inventory availability may be out of date, pricing may be inaccurate, and orders may get lost if the systems encounter connectivity problems.

- Web portal built on direct, real-time ERP integration. Customers get 100% accurate, real-time information from the ERP for availability, pricing, credit status, and more. Interactive messaging from SAP empowers them to create well-formed orders, and only error-free orders can post to the ERP. All orders conform 100% to the customer’s business rules as defined in SAP ERP. No manual intervention from a CSR is required.

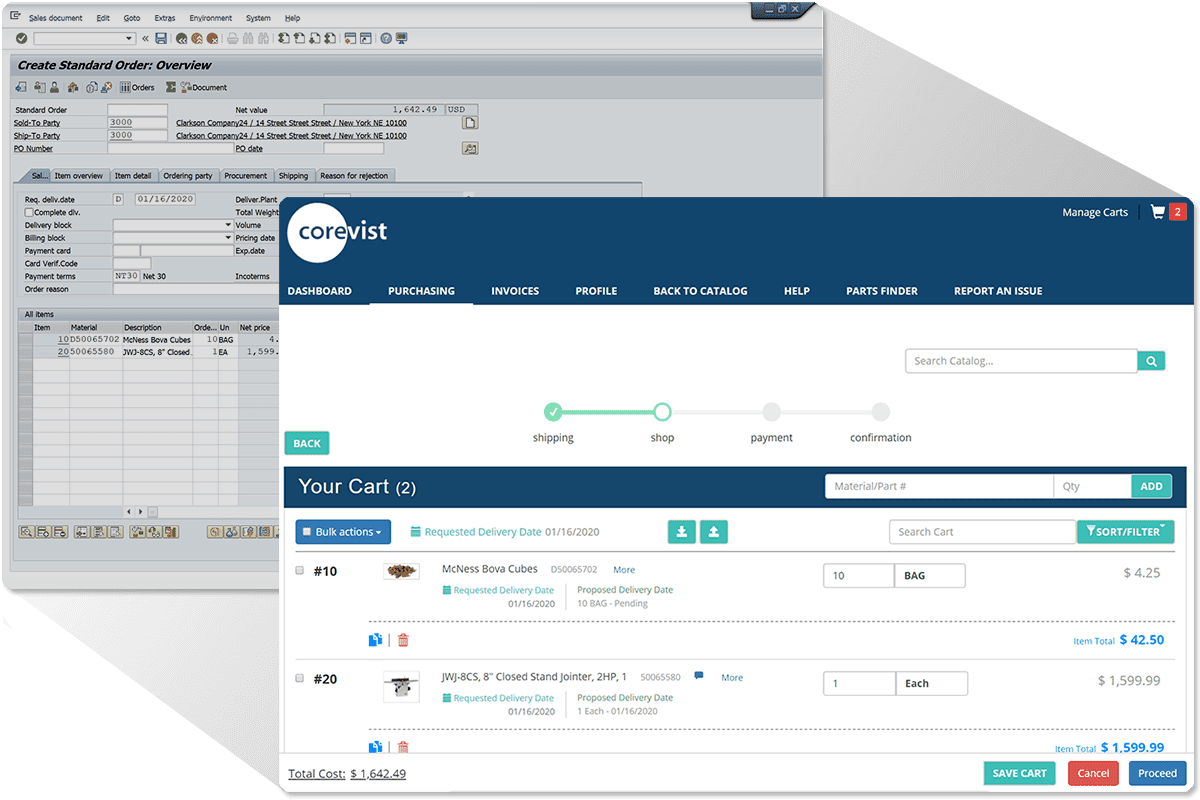

This is the thinking behind Corevist Commerce Cloud, which includes direct, real-time SAP integration that creates a personalized experience for each user:

A solution like this gives your customers everything they need to build and place orders without incurring the cost of a human intermediary. The portal gives your buyers the same data and interaction which they would get over phone, fax, and email:

- Real-time inventory availability (or personalized ATP calculation, if applicable), direct from SAP

- Personalized contract pricing, including any scaled/bundled pricing discounts

- Personalized catalogs/picklists so your customers only see relevant products

- Alternative units of measure for products that can be sold multiple ways

- Smart SKU replacement for discontinued SKUs

- Intelligent error messaging for disallowed/invalid SKUs and/or quantities

- Self-service RDD/EDD from SAP ERP

- Multiple ship-from warehouses so customers can build orders that get to them on time, at the best freight cost

- Upload carts/saved carts so customers don’t have to type in orders every time

Order placement is a great candidate for transitioning to self-service. If your current order placement process requires human interaction that doesn’t provide any additional value, then you stand to gain efficiency in your OTC process with self-service ordering. The key is a deep SAP integration that provides real-time, interactive personalization to each and every customer.

2. Eliminate order errors

All manual ordering methods can produce order errors. Even EDI isn’t foolproof—but email and fax orders are especially prone to errors, as there’s no Customer Service rep on the other end correcting problems in real time.

When orders come in with errors—wrong price, disallowed SKU, disallowed quantity, or similar—they create more work for your Customer Service team. The tasks are varied, depending on the type and severity of the error:

- SKU number error. The intended SKU may be obvious, or it may be impossible to tell what the customer intended. In either case, a manual callback is required.

- Pricing error. Customers may have consulted an out-of-date print catalog—or gotten a price check via phone/fax/email which is no longer valid. However the error occurred, a manual callback is required.

- Disallowed/discontinued SKU. If a customer has placed an order for a SKU which isn’t available to them, your Customer Service team will have to call them back. If there’s an SKU substitution available, the callback is simpler—the CSR can simply suggest the substitution and get the customer’s permission to replace it. If there’s no substitute SKU available, the conversation gets more complex (and costly at scale).

- Disallowed quantity. If you have quantity bundling rules for your products, your customers may place orders for illegal quantities. These will always require manual callbacks to get customers to agree to an allowed quantity.

- RDD (requested delivery date) error. If a customer called in and got a valid RDD date, but neglected to place the order before RDD calculations changed in SAP, they may place an order with an RDD date that’s no longer valid. This will require manual callback, careful explanation to the customer, and acceptance of a new RDD date.

Since well-formed orders are defined by SAP business rules (often with customer-level personalization), it makes sense that you can’t eliminate errors as long as customers can’t interact with SAP in real time.

Here, again, a digital customer portal with real-time SAP integration solves the issue. When you give customers real-time error messaging in the portal, directly from SAP, you empower them to craft well-formed orders on their own—without requiring the assistance of Customer Service. At scale, this kind of customer experience helps eliminate waste in your OTC cycle.

The Takeaway

Legacy order entry methods offer “low-hanging fruit” for OTC optimization. When you launch B2B eCommerce with built-in, real-time SAP integration, you eliminate the need for a costly third party sitting between your customers’ orders and your SAP system. The result is a better customer experience, lower cost to serve, and greater potential for revenue growth.

NEW Report:

Optimizing OTC Processes for Manufacturers

Every manufacturer needs to become more efficient. Here’s the ultimate guide to optimizing your OTC cycle. Read now.