WHITEPAPER

How Today’s Packaging Companies Create Seamless Ordering Lifecycles

Are you battling complex processes and tribal knowledge? Learn how to streamline your data and create a great customer experience.

Packaging companies face unique challenges when it comes to ordering lifecycles. The complexity of customer requirements makes it difficult to envision any sort of process improvement in customer experience. Yet the reliance on humans to store and process business information creates data governance problems. Internally, it’s hard to find one source of truth for data surrounding orders, products, and customer accounts. SAP ERP should be this source of truth, yet due to the complexity of the order-to-cash process, crucial information often lives in sticky notes on your employees’ monitors—or worse, in their heads. This practice leads to lost orders, production delays, and an unnecessarily long order-to-cash cycle. That’s why today’s packaging companies are pursuing strategies that marry a self-service customer portal with SAP ERP data cleansing. Surprisingly, these two initiatives work hand-in-glove to improve customer experience and eliminate waste in internal processes. In this whitepaper, we’ll look at 5 components of a smart transformation plan that you can use to pursue this strategy. But first, we’ll cover the distinction between make-and-ship and warehouse customers. That’s foundational to everything else.

Make-and-ship vs. warehouse customers

Most packaging manufacturers work with 2 types of customers.

- Make-and-ship customers. With lower volumes and faster turnaround times, these customers don’t need warehousing terms. You ship their items out the door once they’ve been manufactured.

- Warehouse customers. These customers have more specialized needs. They often order at higher volumes with longer lead times, but they don’t (or can’t) store inventory themselves. You produce inventory for them and hold it in a warehouse until they need it. They request to release product from their private inventory.

As every packaging company knows, warehousing is essential to compete in the industry. Customers expect you to have a warehouse close to their location where you can store their products until they request to release them. Localized warehousing ensures that lead times aren’t an issue. It also helps customers avoid storage costs and respond to swings in demand. Clearly, warehouse customers have vastly different lifecycles from make-and-ship customers. As we look at tactics for improving your ordering processes, we’ll examine ways in which you can impact both customer convenience and your own operational efficiency for each type of customer. Now, on to the 5 components of a smart transformation plan.

1. Plan to launch a customer portal, but roll it out in phases

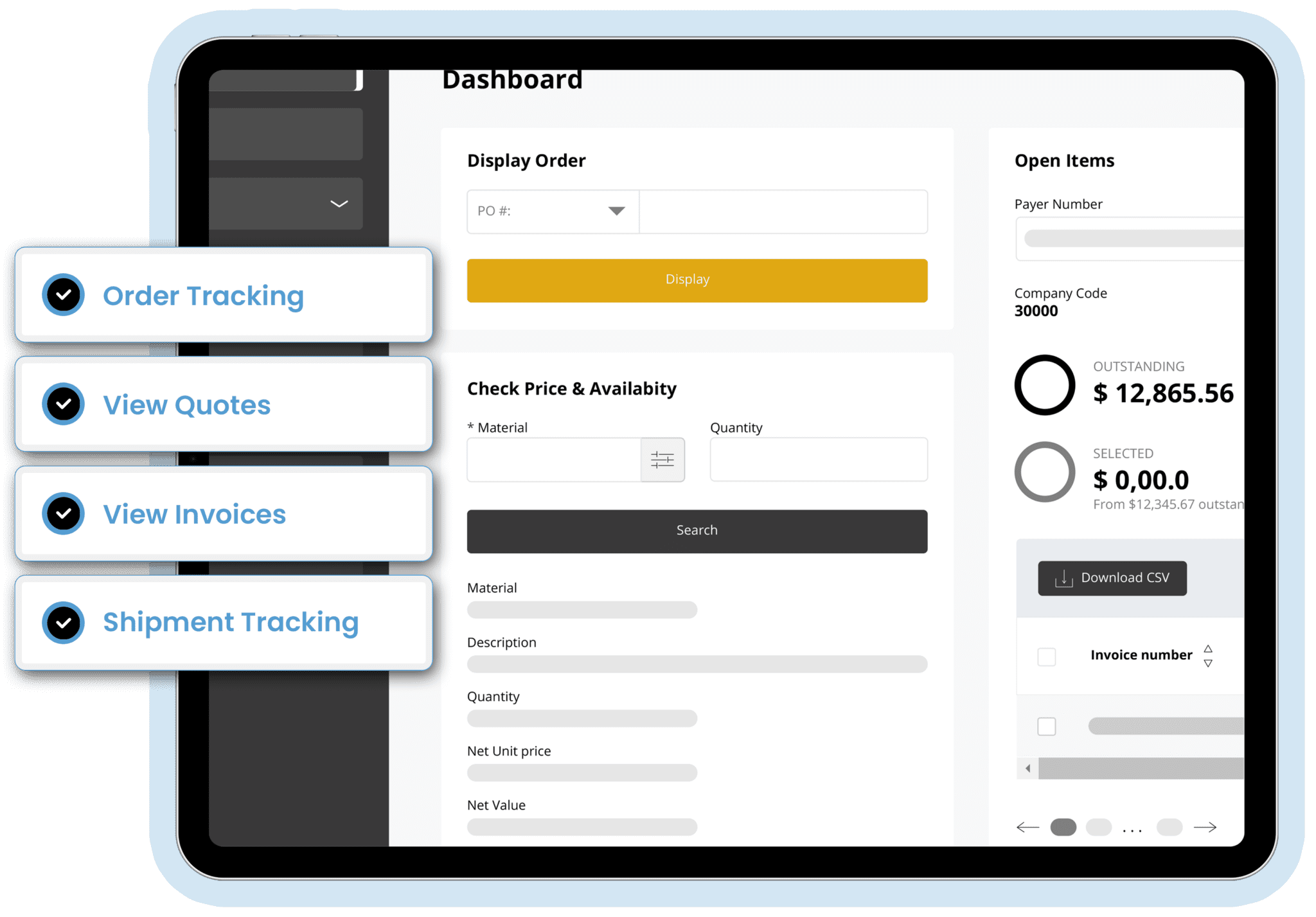

If you’re going to become “easier to do business with,” then you’ll need a self-service customer portal. But this customer portal looks a little different than “B2B eCommerce” in the traditional sense. If every customer gets their own private, custom SKUs, then a product catalog with preexisting SKUs may or may not make sense. Maybe you need that product catalog someday, but it needs to support your SKU creation processes, and you can’t think how to get there today. Maybe you have unique stock-releasing processes for warehouse customers. Your customer portal will definitely need to cover that. If you want to reduce your customer service call load, then the portal will need to provide real-time status for orders and invoices, plus full history for both. You might also want to show real-time credit status, so customers know where they stand—plus self-service invoice payments. Zooming out, here are a few essential high-level components of a self-service portal for packaging customers:

- Simple, intuitive interface that works on any device.

- Login tied to customer ID in SAP ERP so that all data is automatically personalized.

- Deep SAP ERP integration that shows this personalized data in real time, 24×7, with 100% accuracy. You’ll need this to display pricing, inventory availability, status and history for orders and invoices, credit status, and more.

- Support for your stock releasing processes (including SAP integration for those processes, so your SAP data is always correct).

Sounds like a lot, right? Let’s talk about the iterative path to get there. How to roll out your portal in phases Digital transformation projects fail too easily when the scope is too big. That’s why a phased approach is best for packaging companies. The key here is to break up your ordering cycle into phases and plan to roll out one at a time. Tracking orders and invoices is the last leg of the customer journey, but it makes sense to start with this functionality first, as it’s easy to display in the portal (assuming you choose a solution that includes prebuilt integration to SAP). It’s also a great way to introduce customers to self-service. Following that logic, here are the rollout phases that work well for packaging companies:

- Phase 1 – Customer self-service for order tracking and invoices.

- Phase 2 – Add order automation for emailed PO’s (invisible to customers, but valuable to you)

- Phase 3 – Self-service order placement (for all customers) and stock releasing (for warehouse customers)

This is the approach that our client Emmerson Packaging took. When Emmerson migrated onto SAP ERP, they lost their old customer portal, which was integrated to their old ERP. They knew an iterative approach was crucial to restoring customer self-service without taking on a project that was too big to handle.

If you want to roll out in phases, you’ll want to find a portal platform that’s built to support this path. That’s why the Corevist Platform makes it easy to start with self-service post-order care, then add email order automation, order placement, and stock releasing on the same platform.

2. Plan to end your dependence on tribal knowledge

The scope of the problem Tribal knowledge is the bane of packaging companies. Joe in customer service has been with you for 20 years. He fully understands the complexity of your customers’ needs, and he knows how to act as a liaison between the customer and your manufacturing processes. In fact, he’s an expert on your customers, their challenges, and your products. He’s a huge asset. But Joe doesn’t scale. And if he finds a new job, you’ve got a problem. Whether he realizes it or not, Joe also slows down your production process. He’s got a lot on his plate, and even once he gets an order finalized with a customer, he still has to rekey it into SAP. Joe might tell you it takes 5 minutes to enter that order—and that’s true. But Joe has to spend a lot of time with customers beforehand to get that order finalized. How much time does Joe spend figuring out what a customer needs? That’s hard to quantify, but there are certainly delays. Maybe a material doesn’t exist in SAP, or there’s no price, or the customer has specified the wrong product. Both Joe and your newer reps depend on tribal knowledge to hash things out with customers. They use their time and brainpower to make sure an SKU is active, make sure the customer PO matches your SAP logic, and so on. For most packaging companies, that quality check takes 15-30 minutes. Per order. How to end your dependence on tribal knowledge Here’s where you need to make a case and present it to the business. You need to advocate for data cleansing (see below) and a commitment to streamlined business processes. This will empower your reps to spend less time on mundane data problems—and more time acting as sophisticated product advisors. So what does it take? Here are the essential elements of ending your dependence on tribal knowledge.

- Commit to 100% accurate active/inactive status for SKUs in SAP

- Commit to 100% accurate customer pricing for each SKU in SAP

- Commit to 100% accurate real-time inventory data in SAP

With these commitments and a customer portal that’s integrated to SAP, you can actually eliminate those manual quality checks. All it takes is fixing the data, then providing a portal where customers (and customer service reps) can access it in real time.

Believe it or not, you can do this data cleansing in conjunction with the customer portal project. Let’s talk about that.

3. Plan to cleanse your SAP ERP data as you go

You can’t succeed with a customer portal if there isn’t “one true truth” for your business data. If some data lives in SAP, some in the heads of customer service reps, and some in a separate customer portal database, you’re going to have problems. Here’s where an SAP-integrated portal offers a powerful benefit that you won’t get with a standalone portal (i.e. one that has its own database): It forces you to get business processes and data out of people’s heads and sticky notes, and into SAP ERP, where it belongs. This can be hard for some organizations, but it’s entirely worth it—and the process gets easier with a trusted advisor to guide you. Benefits of committing to 100% accurate SAP ERP data

- You become easier to do business with.

- Customers get complete transparency on products, prices, orders, credit status, and more, whether they’re getting the information from a rep or from the portal. Your organization becomes more customer-centric.

- Accurate SAP data correlates directly with faster scheduling. Manual validation processes can add 1-2 days to the process. For packaging SKUs with a 3-week lead time, this creates considerable waste at scale. 100% accurate ERP data allows product to ship within hours of order placement.

- You end your knowledge management problems once and for all, rather than facing them again whenever a seasoned employee leaves and/or you have to hire more reps.

- Standardized processes reduce the chance of errors and increase customer trust, which directly feeds retention.

- Engaging customers in the portal project (and data cleanup project) builds engagement and trust, as it shows you care about their needs.

- You can take advantage of a customer portal platform (like the Corevist Platform) that includes prebuilt integration for ECC or S/4HANA and supports all standard configurations related to the order-to-cash cycle. This means you don’t have to build a risky middleware-based architecture to keep the portal synced with SAP.

How to get your SAP ERP data ready for a customer portal Ideally, you’ll want to find a portal implementation partner who can advise on best practices for configuration. Look for a partner who has deep subject-matter expertise in SAP, SD, OTC, ABAP, and best practices for manufacturers. Hint: This is why the Corevist Team is composed of SAP experts. When we implement the Corevist Platform for a client, we engage a deep, collaborative process to align your SAP configuration not only with Corevist’s requirements, but with general best practices. Depending on your SAP ERP configuration, there are several things that may need to be cleaned up.

- Customer master data

- Orderable products

- Substituted products

- Available to promise (ATP)

- Customer pricing

While you could start cleaning up your data before you engage a partner for your customer portal, it’s best to wait until you’ve selected a platform and partner. That way, all configuration changes will support your future direction as a customer-first organization.

4. Plan to automate email PO’s

Not all aspects of a seamless ordering cycle are obvious to customers. Automating email PO’s is one of those things. Customers won’t necessarily know you’re doing it, but it frees up your reps to spend more time acting as strategic advisors, which directly impacts your value to the customer. What’s more, automated processing gets those orders to production faster. It shortens the ordering cycle for both warehousing and make-and-ship customers. With the lead-times that are typical in the packaging industry, this makes a huge impact. How to automate email PO’s A decent customer portal platform should include the capability to automate email orders and post them to SAP hands-free (assuming there are no errors). That’s the thinking behind Corevist BuyBot (available as an add-on to the Corevist Platform). This automated utility reads incoming PDF orders attached to emails and simulates them against the relevant business rules in SAP. BuyBot checks the customer’s allowable SKUs, contract pricing, quantity rounding rules, and more. If the order doesn’t contain errors, BuyBot posts it to SAP instantly, using the SAP integration architecture that comes with the Corevist Platform. If BuyBot detects errors, it routes the order to your customer service team for review.

5. Plan to offer true self-service order placement

Imagine an ordering process in which a customer builds their own order in a self-service shopping cart, then posts it instantly to SAP ERP. The order doesn’t require manual intervention because it conforms 100% to the relevant SAP business rules. This might sound impossible in the packaging industry, but it’s quite doable. (Just ask Emmerson Packaging.) When you give customers the responsibility to create well-formed orders, you take that responsibility off your plate. You also push customers to know their own needs and your products better. When customers engage more deeply on this level, they gain control over the process, which takes away fear and ambiguity. Empowering customers to place error-free orders Some processes will always require back-and-forth human interaction. If a warehousing customer has highly specific requirements for a new SKU, or if they need expert advice on specifications, your reps will always play a crucial role. But once that process is over and an SKU exists in SAP, why should your subject matter experts (your reps) have to re-key long PO’s into SAP? That’s not a good use of their time. A self-service ordering solution empowers your customers to order those finalized SKUs (and/or release them from warehouse stock) on any device. The key here is to offer a customer portal that’s deeply integrated to SAP ERP. This is the best way to provide essential elements of a self-service ordering experience—things like:

- A catalog that shows only the customer’s unique SKUs

- Real-time inventory availability (including support for complex inventory reports displayed dynamically from SAP)

- 100% accurate contract pricing (including dynamic adjustment for quantity discounts)

- Order placement by CSV upload (to support procurement workflows)

- Intelligent error messaging, driven by SAP responses, to help customers fix problems with their orders before placing them

- Only 100% error-free orders accepted and posted to SAP

The last two points are especially important. This is where you give customers the responsibility to create well-formed orders. You can’t do this if you don’t empower them with intelligent error messaging to help them fix problems. While SAP spits out error responses, you need an additional communication layer in the customer portal to translate those outputs into messages that your customers will understand. A solution like the Corevist Platform takes care of this.

Question: Is this the end of customer service?

Absolutely not! In fact, customers need more human insight than ever when sourcing packaging. The key here is not to replace your reps, but to elevate them. With mundane tasks taken off their plate—things like providing order status, credit status, or entering PO’s into SAP—you empower your reps to put their expertise to use. They can pivot to highly strategic roles as customer advisors and product experts. Ultimately, that benefits everyone involved. Customers get more time with the experts to figure out their needs and design solutions. They also get faster turnaround times on orders. Reps get more rewarding work, as they’re asked to play a crucial, strategic role in customer success. This role requires subject matter expertise, which allows reps to flex their muscles with helpful industry knowledge. Your operations get more efficient, too. With humans taken out of the communication chain for routine actions (order tracking, invoice checking, credit status, inventory checks, order placement, etc.), you speed up your order-to-cash cycle. With reps doing more rewarding work, you should also see less churn in your customer service staff. This gives you more opportunity to grow each rep into a subject matter expert who’s invaluable to customers.

Takeaway: Engage an expert partner to help you plan and execute your path

It’s not enough to tackle this with consultants. And it’s not enough to just buy technology. You’ll get better results with a comprehensive partner who not only knows the packaging industry and SAP, but also builds and supports B2B portals and eCommerce solutions on a best-in-class platform. Here at Corevist, we’ve developed the Corevist Platform over 14 years of solving B2B challenges. The platform includes prebuilt, SAP-certified integration for SAP or S/4HANA, and it supports complex use cases in packaging. We manage and support all our solutions and act as strategic advisors on our clients’ next chapters. Ultimately, that’s a great path to a seamless ordering lifecycle.

Like the sound of this path?

Our core platform launches in 30 days with tracking for orders and invoices. Schedule a consultation and let’s talk about your business problem.