COREVIST EXCLUSIVE REPORT:

7 Strategies To Increase OTC Efficiency For Manufacturers

Every manufacturer needs to increase efficiency. Here are the key challenges of the digital

age—and how to meet them head on.

COREVIST EXCLUSIVE REPORT:

7 Strategies To Increase OTC Efficiency For Manufacturers

Every manufacturer needs to increase efficiency. Here are the key challenges of the digital

age—and how to meet them head on.

Increasing OTC Efficiency for Manufacturers

The digital age has put unique constraints on manufacturers when it comes to efficiency. The traditional OTC (order-to-cash) cycle in manufacturing offers all kinds of opportunities to cut costs and eliminate waste.

So how can manufacturers become more efficient?

Here are 7 strategies to help you streamline your OTC process (click to jump):

1. Eliminate phone inquiries about order/account status

2. Replace manual quote generation processes with self-service

3. Replace phone/fax/email order placement with self-service

4. Eliinate manual inquiries about freight costs

5. Eliminate order errors

6. Give Sales reps a portal for order entry

7. Replace paper-based payment processes with self-service

8. CASE STUDY: 39.2% Revenue Growth

1. Eliminate phone inquiries about order/account status

If you’re reducing waste in your OTC process, where do you start? What low-hanging fruit can you address quickly?

For many manufacturers, manual inquiries about the status of orders, invoices, and credit offer a great opportunity to increase OTC efficiency. This basic information doesn’t require human communication to add nuance or value. There’s no negotiation involved, and no need for the manufacturer to control the conversation. The information requested is simply factual—the status of an order, the credit status of the account, the due date on an invoice.

What’s more, manual presentation of this data isn’t scalable. A Customer Service rep can only serve one customer at a time, so your cost to serve will scale up alongside inquiry volume.

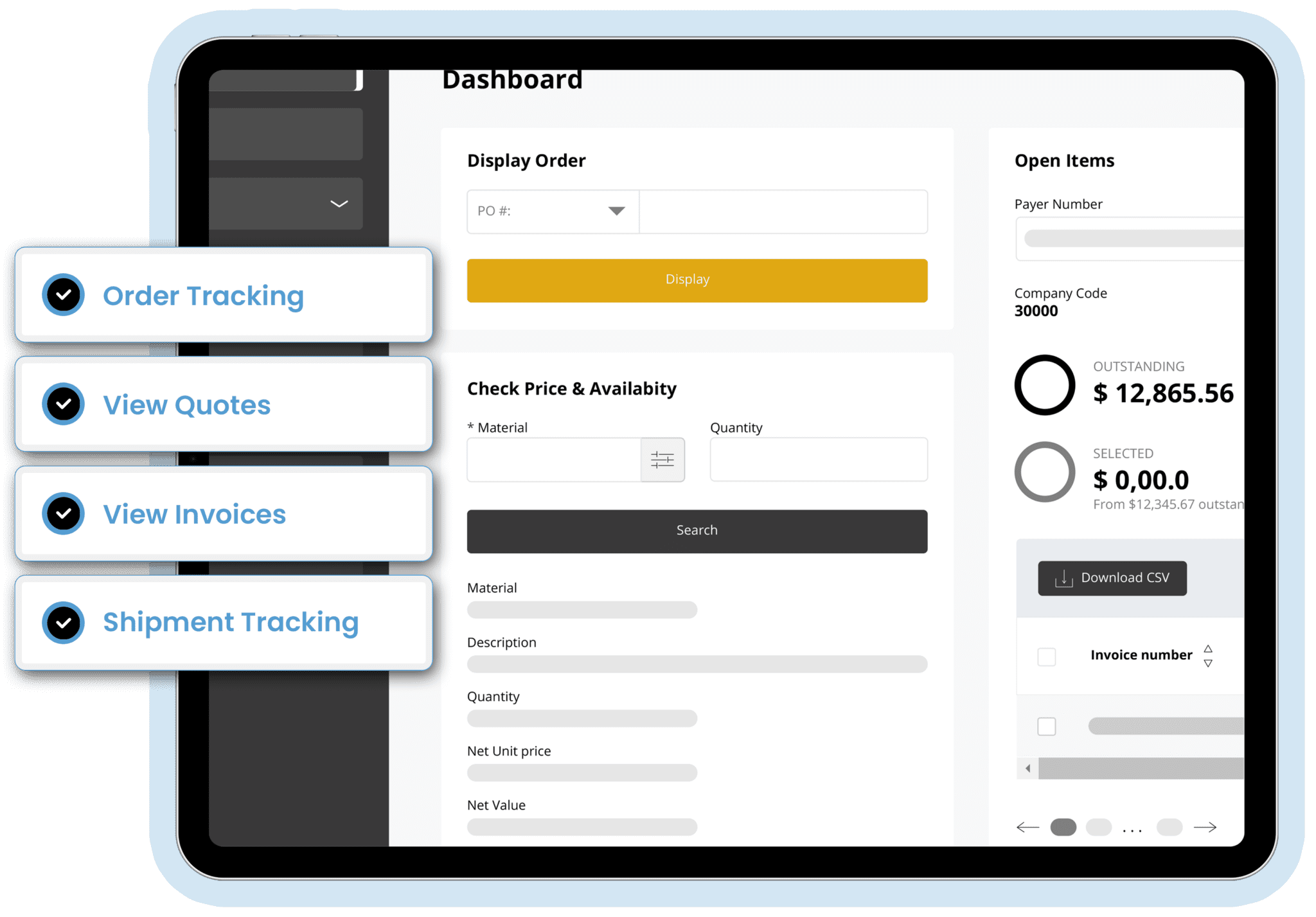

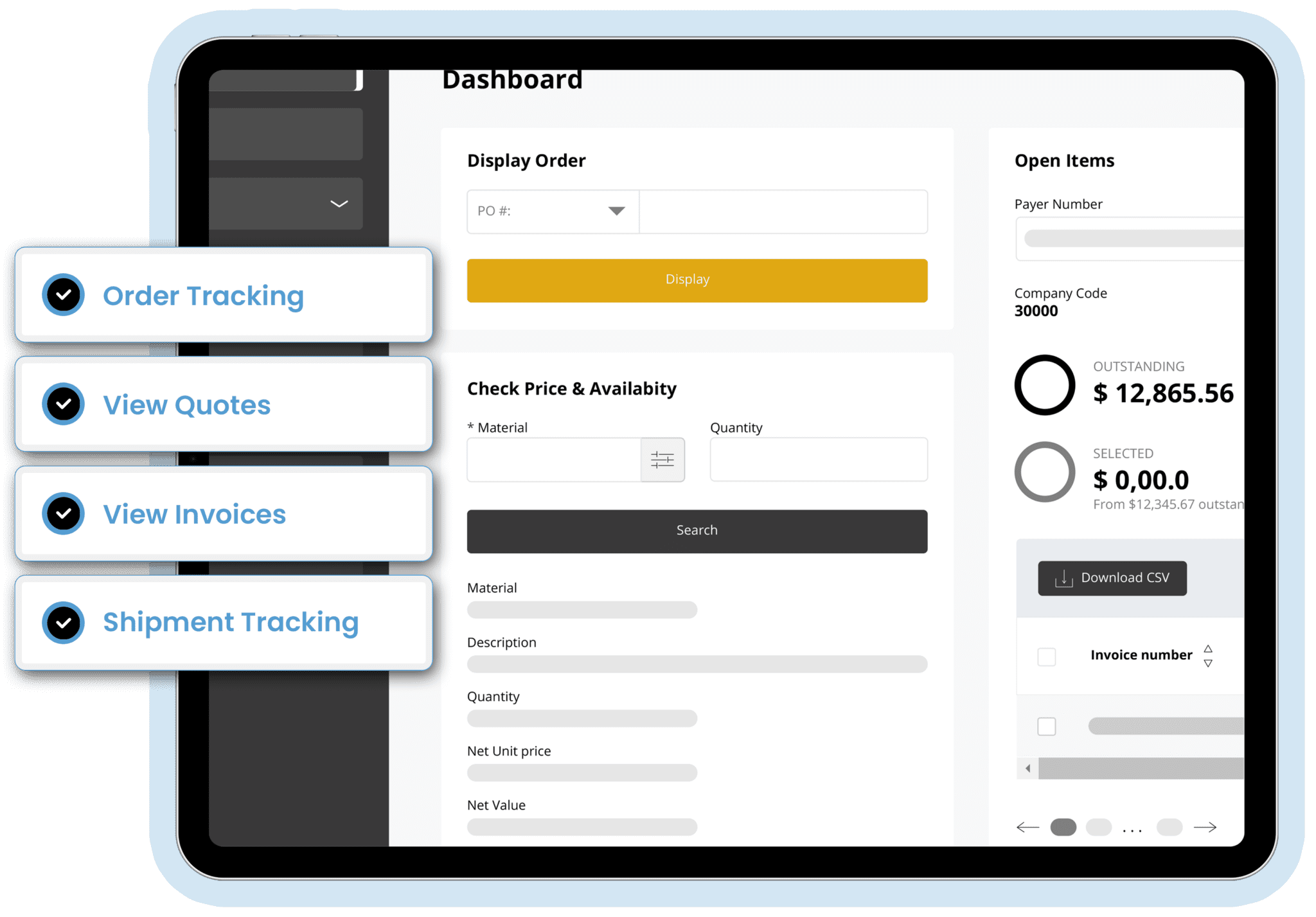

This is why routine inquires are great candidate for transitioning to a self-service digital portal. If you could offer real-time data for orders, invoices, and credit in a digital customer portal, you could eliminate routine status inquiries via phone and email.

If you can move these inquiries to self-service, you’re making great strides. The key is a solution that includes real-time, personalized SAP integration for each customer. (That’s the thinking behind Corevist Order Tracking.)

2. Replace manual quote generation processes with self-service

For many manufacturers, the quoting process is quite complex.

A customer may go through multiple rounds of communication with a sales rep, and the rep may need to gather large amounts of information on the state of the supply chain to give the customer an accurate quote.

While you may not be able to eliminate this underlying complexity, you can simplify the way customers interact with it.

If your quoting process is governed by data and business rules in SAP ERP (e.g. ATP calculations, scaled/personalized pricing, RDD dates, and more), you can make it easier for customers to request quotes. The key is to launch a digital portal solution that supports quote requests—and enforces all personalized SAP ERP business rules which govern the transaction for each unique customer.

This is the thinking behind Corevist Commerce. The solution supports self-service RFQ workflows which conform to your existing SAP business rules.

3. Replace phone/fax/email order placement with self-service

How do your channel partners place orders today? What options do they have if they don’t want to (or can’t) use EDI?

In this situation, most manufacturers rely on phone, fax, or email ordering. The process often includes several steps of manual, back-and-forth communication. To initiate the order process, your channel partners call, email, or fax customer service or sales to ask about pricing and availability. They may take that information back to an approver (if applicable), then call again to place the order.

This process isn’t scalable. Your cost-to-serve scales up alongside order volume, which reduces efficiency in your OTC cycle.

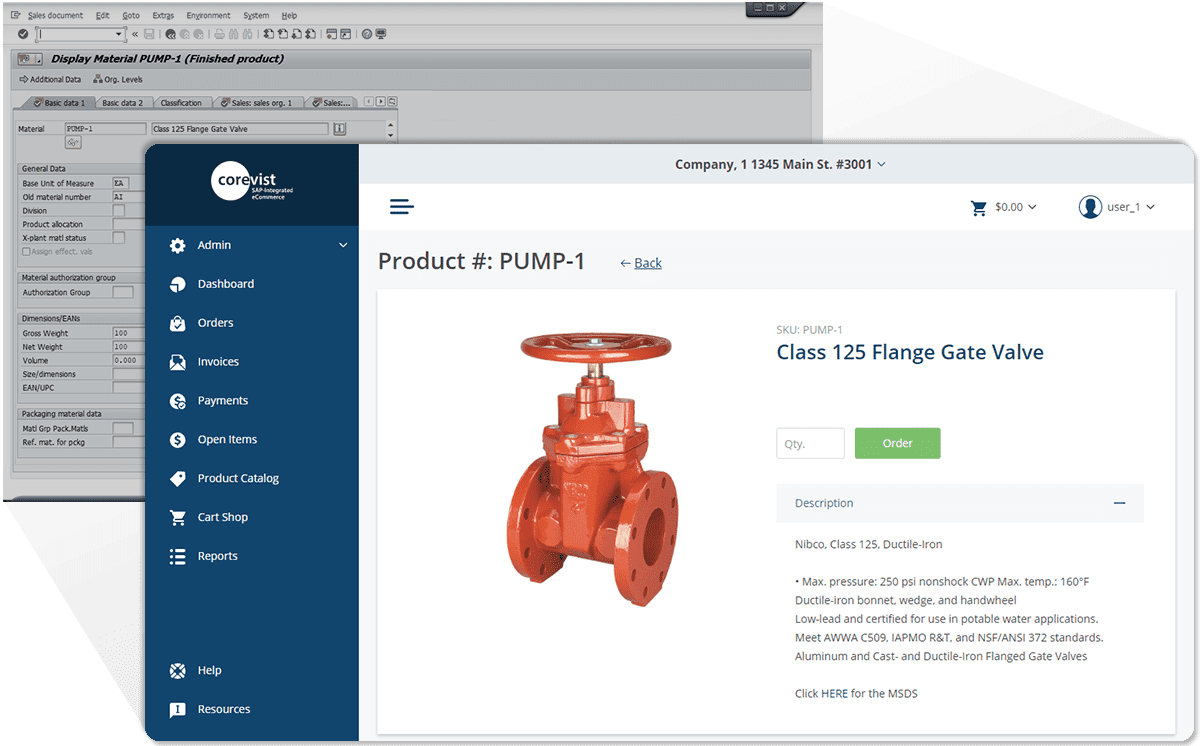

A self-service ordering portal can eliminate the cost of giving the customer personalized data from SAP—but the portal must include real-time SAP integration. That’s the only way to eliminate a high-cost middle layer standing between the order origination point and the ERP.

Here’s what that looks like:

OTC efficiency models – least efficient to most efficient:

- Phone/fax/email ordering (least efficient). Customers must use a legacy communication technology to speak to a CSR (customer service rep), who must re-key the order into the ERP.

- Web portal without ERP integration. Customers can place orders online, but CSRs must re-key those online orders into the ERP (and call customers back to rectify any order errors, disallowed SKUs, wrong quantities/prices, etc.).

- Web portal with batch synchronization to ERP. Customers can place orders online, but the ERP integration isn’t real-time. This means inventory availability may be out of date, pricing may be inaccurate, and orders may get lost if the systems encounter connectivity problems.

- Web portal built on direct, real-time ERP integration. Customers get 100% accurate, real-time information from the ERP for availability, pricing, credit status, and more. Interactive messaging from SAP empowers them to create well-formed orders, and only error-free orders can post to the ERP. All orders conform 100% to the customer’s business rules as defined in SAP ERP. No manual intervention from a CSR is required.

This is the thinking behind Corevist Commerce, which includes direct, real-time SAP integration that creates a personalized experience for each user:

A solution like this gives your customers everything they need to build and place orders without incurring the cost of a human intermediary. The portal gives your buyers the same data and interaction which they would get over phone, fax, and email:

- Real-time inventory availability (or personalized ATP calculation, if applicable), direct from SAP

- Personalized contract pricing, including any scaled/bundled pricing discounts

- Personalized catalogs/picklists so your customers only see relevant products

- Alternative units of measure for products that can be sold multiple ways

- Smart SKU replacement for discontinued SKUs

- Intelligent error messaging for disallowed/invalid SKUs and/or quantities

- Self-service RDD/EDD from SAP ERP

- Multiple ship-from warehouses so customers can build orders that get to them on time, at the best freight cost

- Upload carts/saved carts so customers don’t have to type in orders every time

Order placement is a great candidate for transitioning to self-service. If your current order placement process requires human interaction that doesn’t provide any additional value, then you stand to gain efficiency in your OTC process with self-service ordering. The key is a deep SAP integration that provides real-time, interactive personalization to each and every customer.

4. Eliminate manual inquiries about freight costs

Do your channel partners craft orders to fill up a truckload, so they can save on freight costs?

If so, this is a great place to increase efficiency in your OTC cycle. Getting that information through a CSR (customer service representative) isn’t scalable, as it requires back-and-forth communication—plus manual calculation of product weight to fill up a truckload without going over the limit.

So how do you give your customers full control of truckload utilization (and, thus, optimal freight value)?

Believe it or not, you already have all this information in SAP ERP.

If your SAP ERP system is configured following best practices, each material in SAP should have a weight associated with it. If you have an ordering portal integrated to SAP (like Corevist Commerce), you’ll want to present line item weight and total order weight in the cart. (Corevist supports this functionality).

With visibility into total order weight, your buyers can track the weight of their order as they add products. With line item weight, they can figure out what products to remove from the order if they’ve gone over the limit—or choose the right product to use up the last space on the truck and optimize their freight costs.

Read more here: Personalized Picklists + Lowest Possible Freight Charge.

5. Eliminate order errors

All manual ordering methods can produce order errors. Even EDI isn’t foolproof—but email and fax orders are especially prone to errors, as there’s no Customer Service rep on the other end correcting problems in real time.

When orders come in with errors—wrong price, disallowed SKU, disallowed quantity, or similar—they create more work for your Customer Service team. The tasks are varied, depending on the type and severity of the error:

- SKU number error. The intended SKU may be obvious, or it may be impossible to tell what the customer intended. In either case, a manual callback is required.

- Pricing error. Customers may have consulted an out-of-date print catalog—or gotten a price check via phone/fax/email which is no longer valid. However the error occurred, a manual callback is required.

- Disallowed/discontinued SKU. If a customer has placed an order for a SKU which isn’t available to them, your Customer Service team will have to call them back. If there’s an SKU substitution available, the callback is simpler—the CSR can simply suggest the substitution and get the customer’s permission to replace it. If there’s no substitute SKU available, the conversation gets more complex (and costly at scale).

- Disallowed quantity. If you have quantity bundling rules for your products, your customers may place orders for illegal quantities. These will always require manual callbacks to get customers to agree to an allowed quantity.

- RDD (requested delivery date) error. If a customer called in and got a valid RDD date, but neglected to place the order before RDD calculations changed in SAP, they may place an order with an RDD date that’s no longer valid. This will require manual callback, careful explanation to the customer, and acceptance of a new RDD date.

Since well-formed orders are defined by SAP business rules (often with customer-level personalization), it makes sense that you can’t eliminate errors as long as customers can’t interact with SAP in real time.

Here, again, a digital customer portal with real-time SAP integration solves the issue. When you give customers real-time error messaging in the portal, directly from SAP, you empower them to craft well-formed orders on their own—without requiring the assistance of Customer Service. At scale, this kind of customer experience helps eliminate waste in your OTC cycle.

6. Give Sales reps a portal for order entry

For many manufacturers, Sales reps are an essential part of the OTC process. This is especially true in markets which depend on in-person selling. For many manufacturers, Field Sales reps are the lifeblood of their business.

But the order entry process for Sales reps often has inefficiencies built into it.

If you don’t have a digital order entry portal, your reps will have to call Customer Service to log orders in SAP. Alternately, reps can enter those orders themselves when they get back to the office—but neither workflow is particularly efficient. Each one boils down to “order entry, line by line, via human intermediary.” When that’s the case, there’s always a more efficient way.

A Field Sales Portal is a web-based digital portal which your reps can use from any device. Ideally, it should deliver key functionality through full integration to SAP ERP—things like:

- 100% accurate customer assignment. These relationships live in SAP, so your Field Sales Portal should honor them from SAP with no extra work required.

- 100% accurate inventory, pricing, & more by customer. If your Sales reps are going to build orders in the portal, those orders should conform 100% to the personalized SAP business rules for the assigned customer.

- 100% accurate real-time account standing. Your reps need visibility into credit status, order status & history, invoice status & history, and more. The Field Sales Portal should provide all this information, for each assigned account, straight from SAP ERP.

With a Field Sales Portal in place, you can eliminate the costly back-and-forth of Sales reps calling Customer Service, which eats up paid time for two workers. This is a great place to push for greater efficiency in your OTC cycle.

7. Replace paper-based payment processes with self-service

Are you still depending on paper invoices and checks in the mail to get paid?

If so, your A/R processes offer a prime opportunity to increase efficiency in your OTC cycle. With a digital account portal, you can give customers everything they need to process payments through self-service (as long as the portal includes full integration to SAP ERP):

- View open items in real time from SAP

- View open invoices in real time from SAP

- View credit status in real time from SAP

- Pay open invoices with payment methods of your choice (ACH, credit/debit card, eCheck, Paypal, and more)

- Post transactions instantly to SAP ERP

With a digital account portal in place, you can eliminate inefficient paper-based processes and the back-and-forth communication that they require. This is why A/R offers a great opportunity for increasing operational efficiency.

Wrap Up

No doubt about it, the digital age brings great challenges for manufacturers when it comes to operational efficiency in the OTC cycle. Yet it brings great opportunities, too. The key is to understand your unique OTC challenges and leverage your SAP system for integrated B2B eCommerce.

Want to see this in real life? Check out our case study on PARI Respiratory:

Case Study:

Respiratory equipment manufacturer

1500 employees

Dependent on phone/fax/email ordering